How does the metal coating process work?

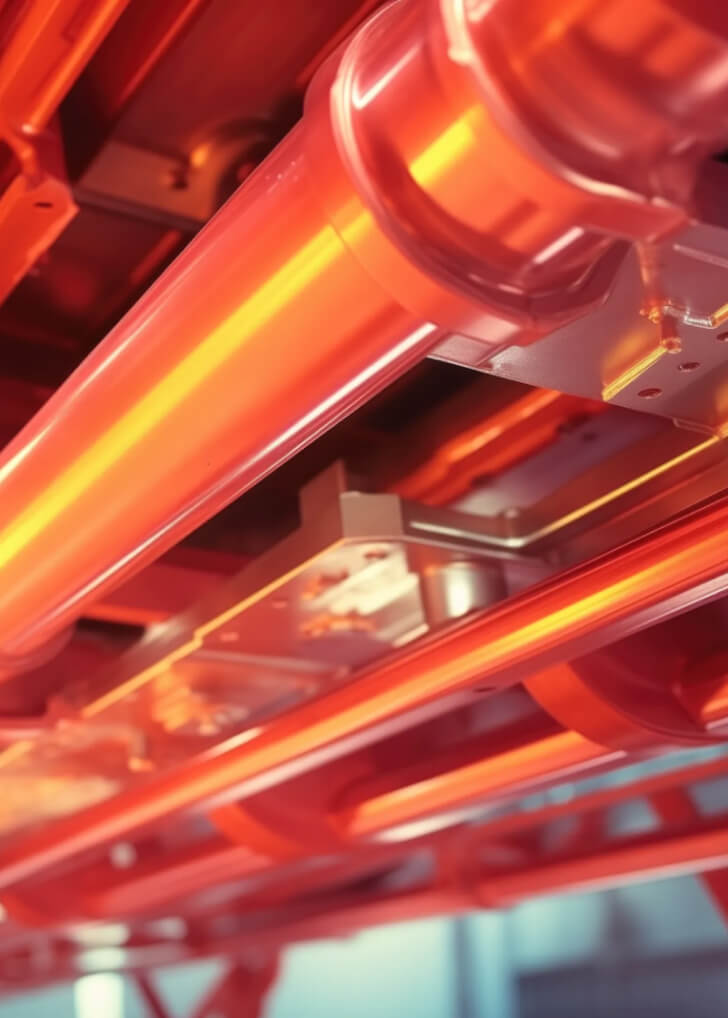

Metal coating is a fundamental process for protecting and decorating metal surfaces. This process involves applying a layer of coating onto the metal surface, which can be done using various techniques such as spraying, brushing, or dipping

The coating acts as a protective barrier against corrosion, preventing the metal from encountering moisture and other atmospheric agents that can cause damage over time. Additionally, metal coating offers pleasing aesthetics, allowing customization of the metal’s appearance according to customer preferences or specific use.

Phases of metal coating

Painting or coating of metal surfaces involves several crucial phases to ensure optimal results. The first phase consists of preparing the surface through a blasting process to remove contaminants, rust, and old coatings using the abrasive action of sand grains or other abrasive substances. Once the preparation phase is complete, the coating application phase begins. This can be done through various techniques, such as spraying, which ensures uniform distribution of the coating on the metal surface. Subsequently, the drying phase follows, during which the applied coating is left to dry completely.

Choosing the right coating

The choice of coating and application method depends on the characteristics of the metal, the environment in which it will be used, and the aesthetic and functional requirements of the project.

- Contact us

Learn more about our metal coating solutions

For more information on surface preparation treatments for metal coating and our solutions, do not hesitate to contact us. Our team of experts is available for personalized consultations and technical details.

The most common types of coatings

Polyurethane resin-based coatings are appreciated for their durability and resistance to impacts, making them suitable for applications requiring a robust and easy-to-clean metal surface, such as machinery or industrial equipment surfaces.